Summer 2019 saw MJ Finnigan successfully complete a large demolition project in the City Centre of Manchester. The contract was placed directly with the Mayfield Partnership including U&I, LCR, Manchester City Council and Transport for Greater Manchester.

This contract was very high profile given its location adjacent to Piccadilly Train Station and the Mancunian way and is the largest regeneration project in the city so it was crucial that the right demolition contractor was appointed.

Mayfield will become home to over 10,000 jobs, 75,000 m2 of new commercial office space, retail and hotel accommodation, as well as more than 1,400 homes and community uses. These various phases will include a large part of the Mayfield Park which will help to breathe new life into this 24-acre derelict site, creating a thriving £1.1 billion mixed-use neighbourhood.

During the works, MJ Finnigan also adopted to the rapidly changing site conditions in delivering a variation in the form of an enabling works ground works package for the opening of a live public food and drink area, now renowned as ‘Escape to Freight Island‘

The site also had other high profile events due to commence post contract completion so it was imperative the works were completed on time. These included the Manchester “Pride” festival and the world famous “Warehouse project”.

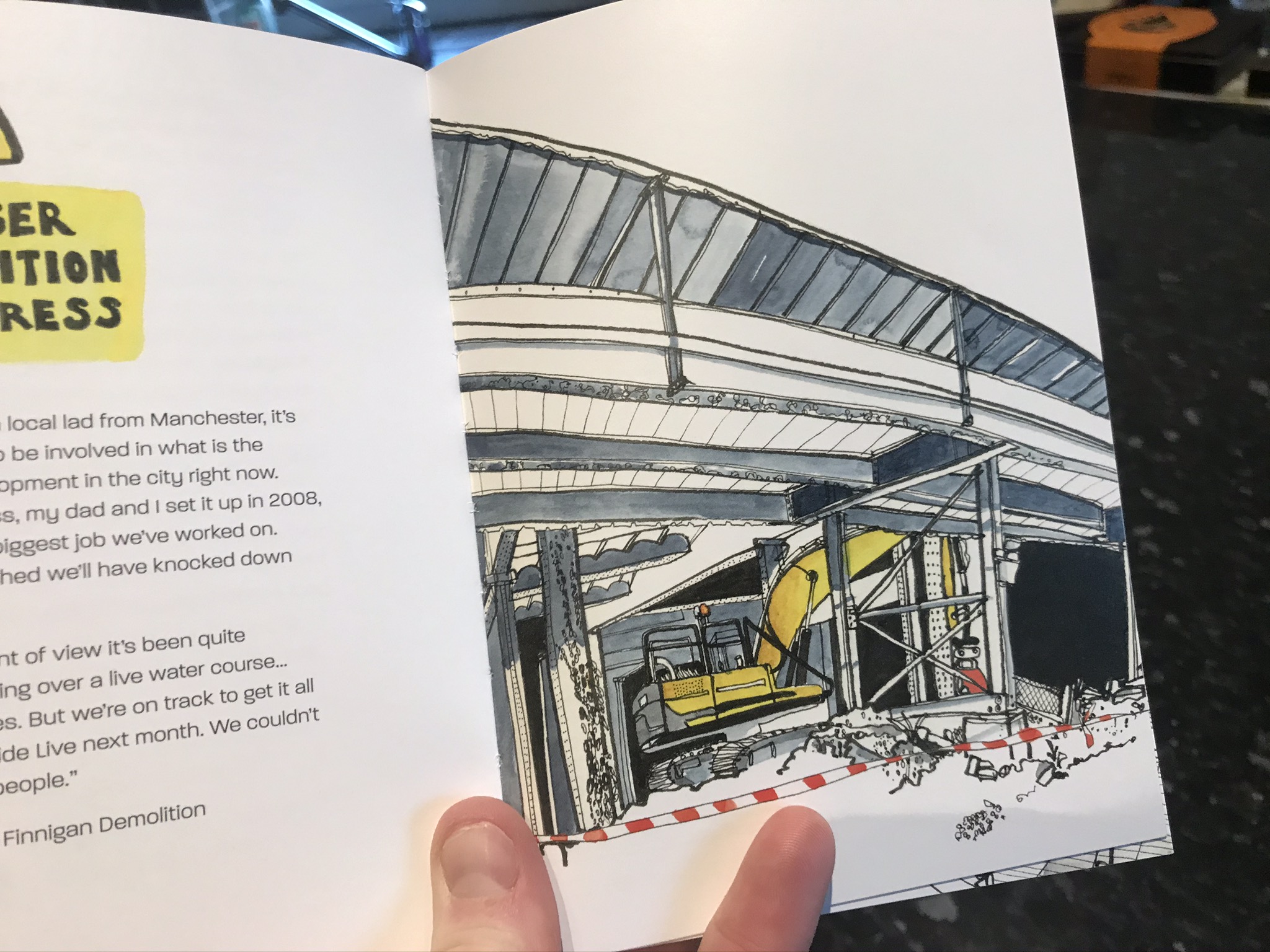

The challenges on site were numerous and included live water courses with buildings backing onto the River Medlock, close proximity of the retained buildings and client offices, a live river culvert with weight and loading restrictions, busy roads and many others. The contract scope also included for the commissioning and co-ordination of the disconnection of the complex utilities on site including gas, water and electricity.

This was all programmed accurately to allow the project to complete without delay. MJF Demolition carried out the work in a diligent and safety conscious manner when carrying out all of their activities which allowed the £1m project to be delivered on time and without accident or incident.

The scale of the site can be seen here:

One of the stand out challenges of the project was the discovery of significant quantities of polystyrene contamination in the cavity walls during the demolition of the tow bar and church buildings. These structures were extremely complexed in their below ground construction, and went down to a depth of approximately 20 metres, which required complex vacuum excavation techniques to remove the waste and allow for the building to be demolished, without contaminating the hardcore and the adjacent river Medlock.

Another challenge was to demolish the old network rail ramp structure. The structural integrity was compromised due to the aged nature of the ramp combined with the close proximity to adjacent river culvert and depot building as well as key access routes. As such, a unique demolition approach was necessary to overcome these constraints.

The company experts sought to develop a bespoke methodology to safely deconstruct the ramp steel structure whilst maintaining structural integrity and operational safety. Due to the unique configuration of the ramp which was constructed with steel and had pre-cast concrete foundations, the company sought to minimise the implied loads upon the structure during the demolition process particularly with the development of an innovative structural.

To this end, a demolition and dismantling strategy was developed to ensure improved safety factors whilst not incurring and transferring additional weight loadings onto the fragile structure by utilising a combination of machinery including a robot for remote demolition that was specifically integrated in this strategy to meet these demanding constraints. To further stabilise the ramp, the research team designed bespoke structural bracing to provide support to the structure and prevent uncontrolled collapsing when operated with heavy machinery during the deconstruction process.

To deconstruct and remove the ramp, the company experts developed unique access and dismantling methodologies to overcome structural fatigue and machine loadings whilst maintaining operational safety. The removal methods applied encountered severe technical challenges due to the uncertainty of the stability and doubts regarding the behaviour of the structure during the process with a high probability of collapsing into the river from one side or on the depot building from the other side.

To overcome this, the company started by carrying out loading tests over the river culvert and developed a solution consisting of a complex haul road design on the banks of the river to enable the safe access of the heavy demolition crane and carry its weight.

After ensuring plant machinery access the company employed the use of a robot onto the ramp to test its load bearing capacity and to penetrate into the concrete in order to expose the steel sections and then the crane was utilised for dismantling. Furthermore, to ensure the safety of this operation, the company designed and installed a bespoke structural bracing to further support the structure and prevent it from collapsing. This required substantial FEA7 modelling and structural analysis along with design iterations to ensure the weight was evenly distributed and all load paths were accounted for, as well as ensuring that the necessary stability could be achieved during the deployment of this phased methodology and process to remove steel component sections and detach them from the rest of the structure.